In the realm of market demands, the quest for resilient, adaptable, and economical packaging solutions has never been more vigorous. Among a number of material choices, polypropylene packaging distinguishes itself due to its exceptional attributes and adaptability. Gaining insight into the common uses and applications of this prominent packaging can empower businesses and end-users in their decision-making processes.

What Is Polypropylene?

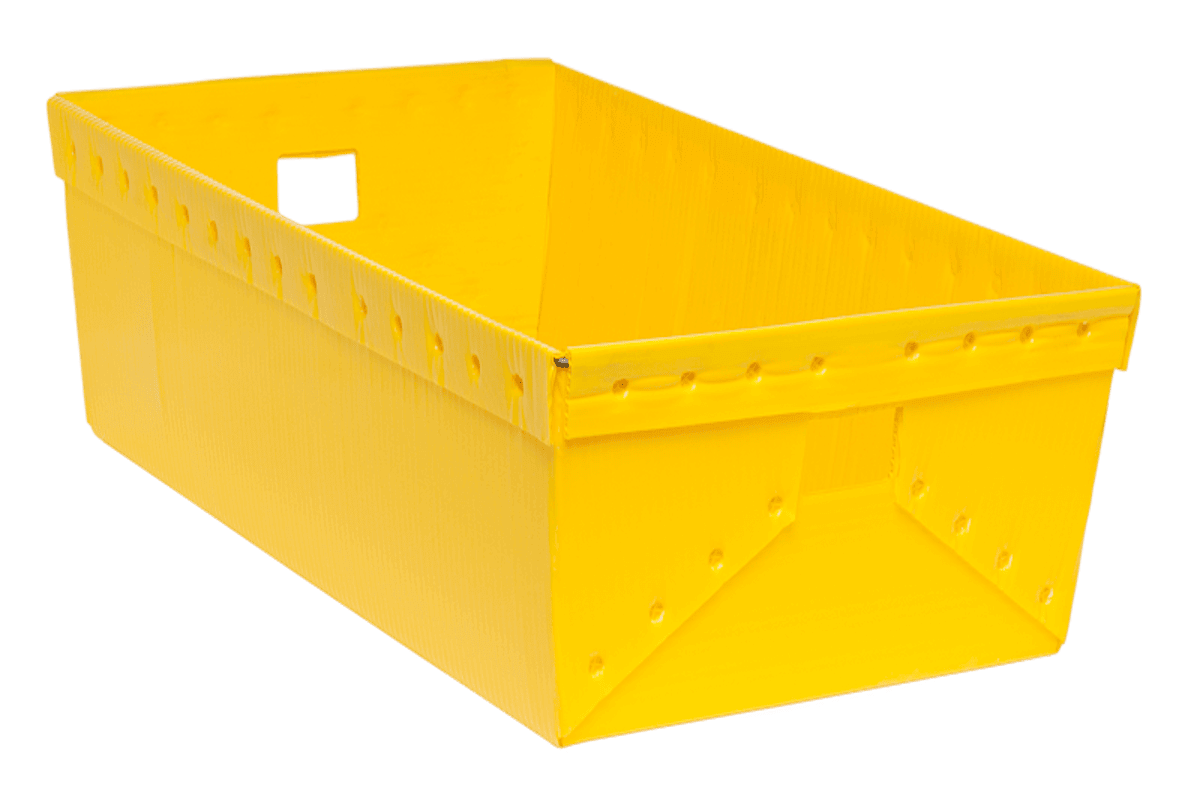

Before we explore its wide-ranging applications, comprehending what polypropylene entails is fundamental. Polypropylene, or PP, is a thermoplastic “addition polymer” made from the amalgamation of propylene monomers. It’s renowned for its toughness, clarity, chemical resistance, and its ability as a barrier against various environmental factors, solidifying its status as a go-to material in the packaging sector.

Properties That Make Polypropylene Desirable

Polypropylene boasts several innate properties that contribute to its widespread appeal in packaging. It’s simultaneously lightweight and robust, resists environmental changes, and exhibits no reaction with water, detergents, acids, or bases. The resilience and ability of this material to retain its form and strength under duress and high temperatures are pivotal to its extensive application in packaging.

Common Uses in Various Industries

The versatility of polypropylene makes it a preferred choice for a host of packaging applications. Its deployment is omnipresent across numerous industries, attributable to its multifunctionality and efficacy in safeguarding products from environmental nuisances.

Food and Beverage Industry

The food and beverage sector marks one of the paramount applications of polypropylene packaging. Its impermeability to water, durability at high temperatures, and resistance to various chemicals make PP the preferred material for containers for an array of consumables and drinks. It safeguards food from microbial infiltration and other pollutants, thereby prolonging shelf life and preserving quality.

Healthcare and Pharmaceuticals

In healthcare, polypropylene containers are quintessential for preserving the sterility of medical supplies, medications, and surgical tools. Its chemical inertness ensures zero interaction with its contents, preserving their purity. Moreover, polypropylene’s high-temperature tolerance means it can be autoclaved, a necessity for items demanding stringent sterility standards.

Consumer Goods and Electronics

Polypropylene’s antistatic property is a boon for the consumer electronics sector, making it ideal for housing sensitive electronic components that could otherwise be jeopardized by electrostatic discharge. Its sturdiness and resilience also cater to the needs of products requiring durability during transit or prolonged usage. Cosmetics and Personal Care In cosmetics and personal care, polypropylene’s chemical steadfastness and aesthetic versatility are highly prized. It’s a standard for packaging various beauty and personal care products, with its amenability to coloring and formability contributing to its suitability for visually-driven branding.

Cosmetics and Personal Care

In cosmetics and personal care, polypropylene’s chemical steadfastness and aesthetic versatility are highly prized. It’s a standard for packaging various beauty and personal care products, with its amenability to coloring and formability contributing to its suitability for visually-driven branding.

Environmental Impact and Sustainability

With growing environmental apprehensions, the sustainability of polypropylene packaging is a significant discussion. PP is among the more eco-friendly plastics, being recyclable and having a lower ecological footprint than many alternatives. Continuous advancements are underway to enhance the eco-friendliness of polypropylene packaging, including better recycling technologies and the advent of bio-based polypropylene.

Conclusion

Reflecting on its broad spectrum of applications and benefits, polypropylene packaging emerges as a critical player across diverse global industries. Its unique fusion of durability, safety, and cost-effectiveness renders it an invaluable asset in the packaging sphere. Recognizing the common uses and applications of polypropylene packaging allows for ongoing innovation and informed choices, potentially steering us towards a greener packaging future.

For further insights or inquiries, please feel free to contact MDI today. Our team is ready to assist you in navigating the complex choices surrounding your packaging needs.