In the expansive world of packaging, polyethylene is a superstar material, celebrated for its myriad applications across countless sectors. Known for its versatility, resilience, and cost-effectiveness, it’s a preferred choice in various industries, playing a critical role in our daily routines and the broader economy. This article explores the common uses and applications of polyethylene packaging, emphasizing its essential function in our contemporary lives and industrial activities.

What Is Polyethylene Packaging?

Polyethylene packaging is everywhere, from your household items to the products you receive from online shopping. Understanding its nature, types, and history helps consumers and manufacturers alike to appreciate its value and vast potential.

Polyethylene, a thermoplastic resin born from the polymerization of ethylene gas, is appreciated for its lightweight nature, resistance to chemicals, and robustness. It comes in several varieties, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE), each with its own set of attributes and advantages.

Common Applications of Polyethylene Packaging Materials

The sectors relying on polyethylene packaging are diverse, ranging from food and health to electronics and agriculture. Its universal presence is a testament to its functionality, efficiency, and adaptability in meeting various industrial requirements.

Food and Beverage Industry

Polyethylene food packaging is a common sight in the food and beverage industry. It safeguards everything from fresh fruits to frozen items and liquids, thanks to its exceptional ability to resist moisture and preserve freshness. For example, HDPE is the material of choice for milk containers, while LDPE is favored for its flexibility in products like squeezable bottles and film wraps.

Medical and Pharmaceutical Sector

The medical sector depends heavily on the hygienic and protective nature of polyethylene product packaging. Its resistance to contamination and precise engineering capabilities make it perfect for items such as medicinal containers, syringes, and sterile wraps for medical instruments. Its adaptability and strength are especially important for child-resistant and tamper-evident pharmaceutical packaging.

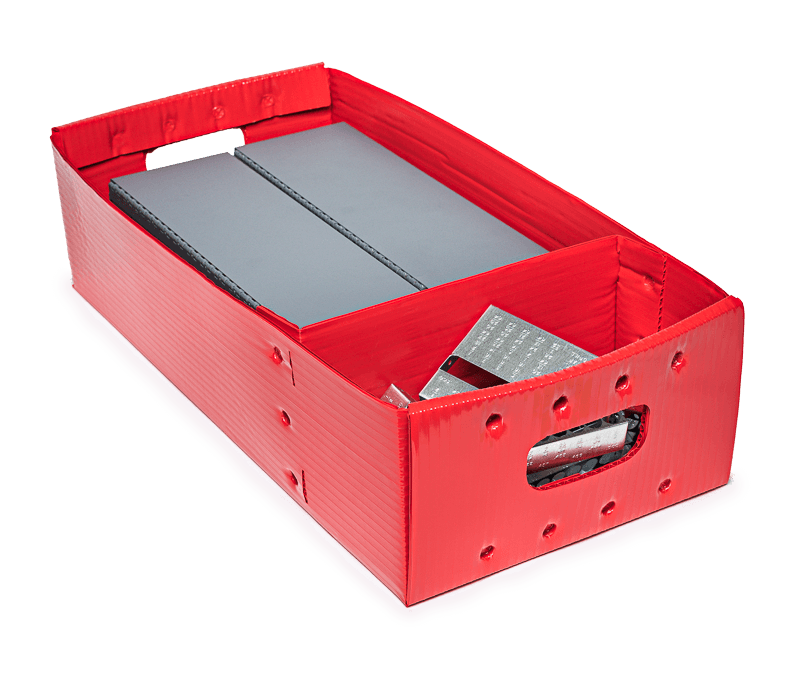

Consumer Goods and Electronics

In the realm of consumer goods, polyethylene packaging solutions provide a lightweight, sturdy, and economical method to safeguard products during transportation. Electronics benefit particularly from anti-static polyethylene bags that prevent static electricity, protecting sensitive components from electrostatic discharge during movement or storage.

Agricultural Applications

In agriculture, the usefulness of polyethylene extends beyond product packaging to structural applications. High-strength polyethylene films are crucial in greenhouses, creating a controlled cultivation environment by managing temperature, humidity, and light. Furthermore, UV-resistant polyethylene packaging is essential for storing and shipping agricultural products, providing protection from sunlight and decay.

Environmental Impact and Sustainability

As the conversation around environmental conservation gains momentum, the recyclability and sustainable alternatives of polyethylene packaging come under scrutiny. The industry’s response through innovative measures is shaping the future of packaging, making it more eco-friendly and sustainable.

Recyclability of Polyethylene Materials

One significant benefit of polyethylene packaging is its recyclability. Both HDPE and LDPE materials are commonly recognized in recycling programs, positioning them as more eco-friendly alternatives to many other plastics. Recycled polyethylene can be reformed into new packaging, minimizing waste and reliance on virgin materials.

The Drive for Bio-based Polyethylene

Amid escalating environmental concerns, there’s a surge in interest for bio-based polyethylene, derived from renewable sources like sugarcane, as a substitute for conventional petroleum-based polyethylene. This transition reduces the carbon footprint and offers a sustainable packaging option without sacrificing the advantageous properties of the material.

Conclusion

The common uses and applications of polyethylene packaging highlight its undeniable presence and critical role in modern society. Its integration into various aspects of our lives speaks volumes about its utility, necessity, and the continuous innovations aimed at making it more sustainable and environmentally friendly.

For more insights or inquiries on polyethylene packaging solutions, please feel free to contact MDI today. Our team is ready to assist you with expert advice and information.