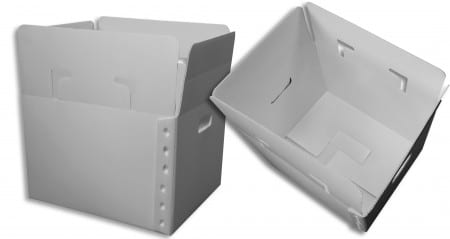

For those in distribution, material-handling and manufacturing, containers can be a large portion of business cost and waste. The reusable, regular-slotted container (RSC) produced by MDI improves both of those metrics, creating a closed-loop system that is more sustainable and cost-effective.

The reusable box helps meet cost-cutting goals by paying for itself in as little as 12 uses, compared with cardboard. It reduces costs associated with breaking down, erecting, storing and disposing of cardboard. In addition, MDI testing confirms corrugated plastic containers last up to two years, depending on the application. This is a vast improvement over cardboard, which typically last a month or less – helping companies achieve sustainability objectives.

“Our customers have rigorous continuous-improvement goals,” said Bob Green, national account manager at MDI. “Solutions like this container help our customers save money and time, while being a better community member. As a social enterprise, we understand the need to find solutions that serve multiple purposes. MDI boxes are produced in an inclusive work environment where people with and without disabilities work side by side. Every time we help a customer, we are also providing jobs to people who might otherwise not have the opportunity to work.”

Available in both polypropylene and polyethylene, 100 percent recyclable containers are welded together for greater strength and longevity. MDI can produce the box in a variety of standard or custom configurations, sizes, add-on options, weights and colors. The boxes expand on the organization’s vertically integrated manufacturing, product assembly and kitting services.

Click to learn more about the RSC.