In the world of industrial packaging, material choice is paramount to the success of product protection and transportation. One popular material that has gained significant attention over the years is polyethylene. As a prospective customer seeking a packaging solution that aligns with your business needs, understanding the pros and cons of polyethylene packaging is essential.

In this comprehensive guide, we’ll examine why polyethylene is a preferred material at MDI, the manufacturing processes involved, and the unique characteristics that make it stand out.

What Is Polyethylene?

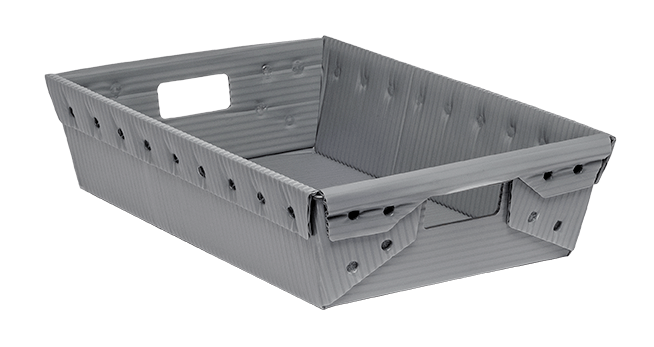

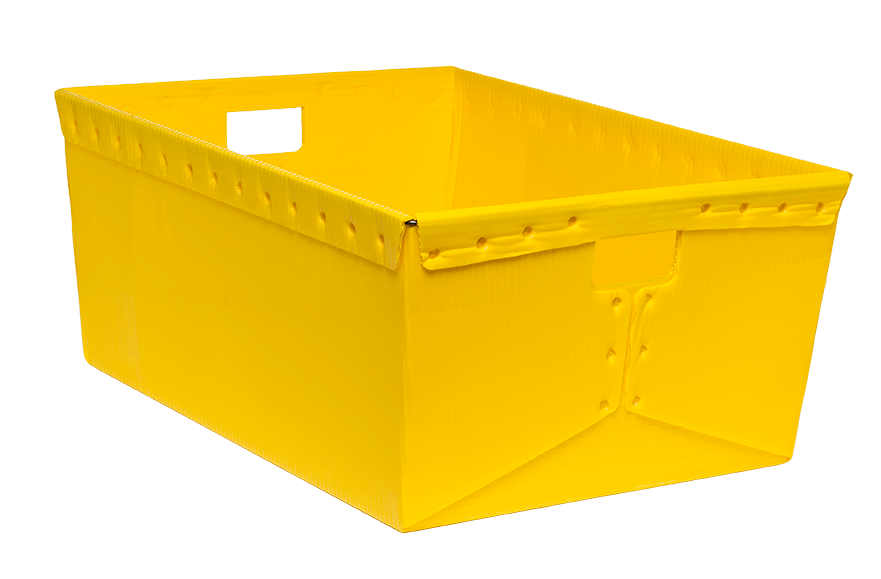

Polyethylene is a widely used plastic known for its soft texture yet durable characteristics. It is the choice material for making totes and trays with wire rims. Here’s an overview of what makes polyethylene packaging so popular.

The Pros of Using Polyethylene

Durability and Performance

At MDI, polyethylene is favored for its exceptional durability. Products like totes and trays made from this material have been known to remain in the system for over five years. This durability is due to several key factors:

- Softer plastic: Unlike other plastics, polyethylene is softer, allowing it to absorb shocks and impacts better, thereby preventing damage.

- Temperature resistance: Polyethylene packaging can withstand different temperatures, making it suitable for conveyor systems in and out of various environments, including snow, rain, and heat.

- Millions of times over: MDI has produced polyethylene totes and trays millions of times, showcasing the trust and reliability in the material.

Conveyor Systems Compatibility

Polyethylene’s adaptability is seen in its compatibility with conveyor systems. Since many products must go in and out of different buildings and temperatures, polyethylene’s resilience to environmental factors plays a vital role.

The Cons of Using Polyethylene

While polyethylene offers several advantages, it is essential to consider potential drawbacks in the context of your specific needs:

- Environmental concerns: Like many plastics, improper disposal can lead to environmental issues.

- Potential cost factors: Depending on your requirements, the cost of polyethylene packaging may or may not align with your budget constraints.

Learn More About the Pros and Cons of Polyethylene Packaging

Choosing the right packaging material is a critical decision that requires careful consideration of various factors. By understanding the pros and cons of polyethylene packaging, you can make an informed decision that aligns with your product’s specific needs and your company’s budget.

At MDI, we take pride in our expertise in producing polyethylene totes and trays, recognizing its softer texture, durability, and compatibility with various systems. We hope this guide has provided you with the insights needed to evaluate polyethylene as an option for your packaging needs. Contact MDI today to learn more about the pros and cons of polyethylene packaging.